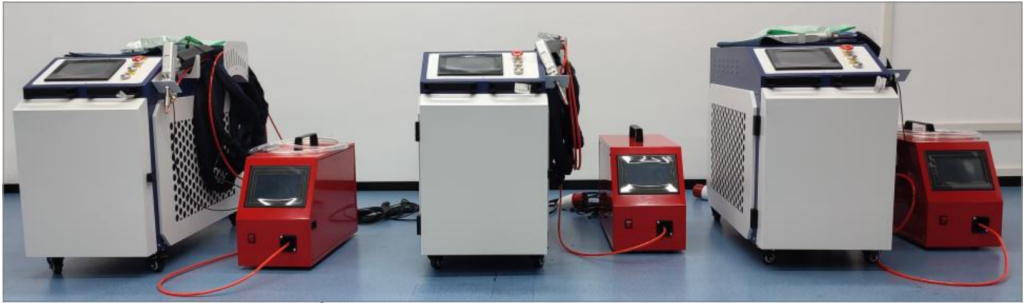

HANDHELD LASER WELDING MACHINE

HANDHELD LASER WELDING MACHINE

Product advantages:

The laser welding machine adopts fiber laser, which has high photoelectric conversion efficiency and

long life of 100,000 hours. The energy provided by electric energy is 25%-30% converted into laser

energy, and the photoelectric conversion rate is many times than that of YAG laser.

Features:

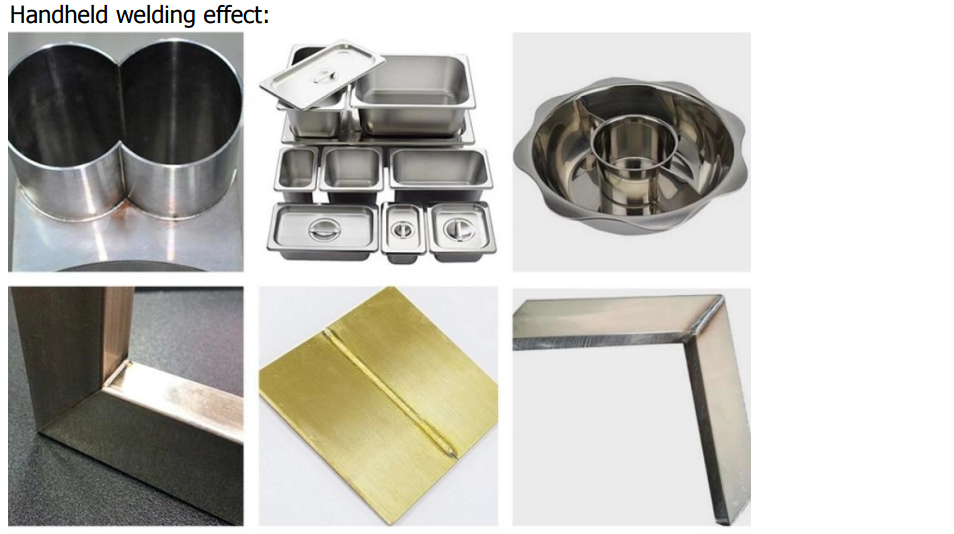

- The energy density is high, the heat input is low, the amount of thermal deformation is small, and the

melting zone and the heat-affected zone are narrow and deep. 2. High cooling rate, which can weld fine weld structure and good joint performance. 3. Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily

maintenance costs and greatly increasing work efficiency. 4. The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the

appearance is smooth, flat and beautiful. 5. No consumables, small size, flexible processing, low operating and maintenance costs. 6. The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot. Application areas:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industries.

Technology parameters

Laser power 1500W/2000W/3000W

Center wavelength 1080nm

Output power stability <3%

Laser frequency 50Hz-5KHz

Adjustable power range 10-100%

Beam quality 1.1

Optimal operating environment Temperature 0-40 ° C, humidity 20% -80%

Electricity demand AC220V (1500w, 2000w), AC380V (3000W)

Output fiber length 10m

Cooling method Chiller inside

Total power 7kw(1500w); 9KW(2000w); 13KW(3000w)

Advantages:

- Simple and easy to learn, no professional welding master is needed, ordinary workers can be used

proficiently after short-term training. Long-term use can greatly save processing costs, and the

electro-optical conversion efficiency is high, and the energy consumption is low. 2. Small footprint, convenient and flexible; the integrated cabinet integrates the laser source, chiller, software control, etc., and the handheld welding head is equipped with 10 meters of optical fiber, which

is flexible and convenient. 3. Welding is formed at one time, basically without deformation, can weld various complex welded

workpieces and large workpieces with irregular shapes, and realize welding at any angle. 4. The welding area has little heat influence, is not easy to deform, does not blacken, the welding depth

is large, the welding seam is beautiful, there is no welding scar, no grinding, and the welding is firm, and

the welding seam strength reaches or exceeds the base material itself. 5. The touch switch is equipped with a safety clip, and the laser beam can only be emitted when the

welding nozzle touches the metal. 6. Red light positioning is used to verify the position during welding.

Our machines have applications in the following companies:

Pre-sale service

1.According to customer requirement, we provide you with the relevant professional technology information (including

the specification, machine pictures, working videos, manual) and test samples by our machines. 2.Welcome to visit our company, we will let our engineer do marking or welding on samples. Seeing is believing, and

it is better for future business. 3.We offer a reasonable price for mutual win-win cooperation.

Sale service

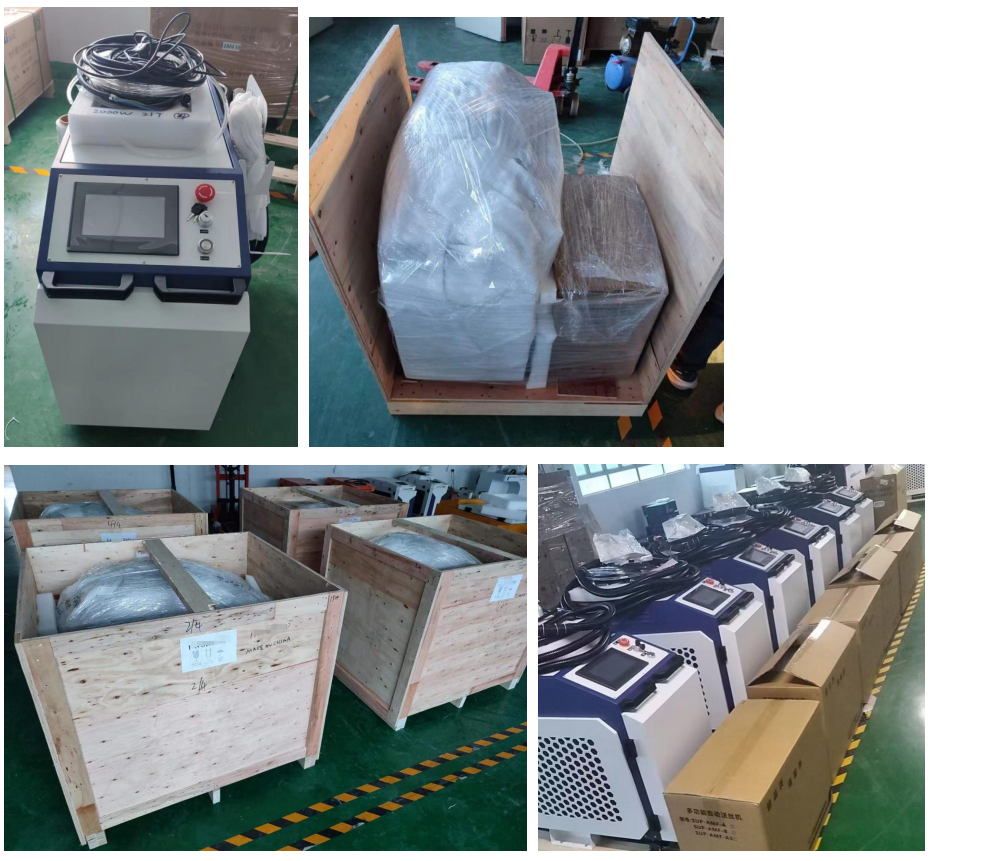

We will make a working video and take pictures to customers for confirmation before delivery (within 15 days after

receiving the total payment). 2. Machine will be packed into the standard wooden cartons, suitable for vessel or air transport, and marked the

universal label, shipping marks. 3.Send customers commercial invoice, packing list, BL or AWB sheet, optional CO or FF or FTA or SASO for

customer custom clearance.

After-sale service

Warranty and Service included:

a. Hardware: one year warranty;

b. Software: whole life on update for free. c. Maintenance and technological support: whole life.